Today I thought I would share a great way to take your garment

sewing to the next level with a grosgrain waist stay. A waist stay relieves tension on a garment at its tightest point and helps to support the weight of the fabric. It also keeps seams and zippers from being strained during wear. As an added bonus, it can serve as an extra pair of hands when trying to zip/snap/hook/button yourself into the garment!

And if you are a fan of strapless garments, a waist stay is invaluable. These days many clothing manufacturers use a rubberized strip at the upper edge to keep a dress in place - having developed a rash from wearing one for a few hours, I refuse to go that route. Stabilizing the dress from the waist or under the bust is so much more comfortable and secure!

There are two types of grosgrain ribbon that make an

excellent stay. Grosgrain commonly found in craft stores is made from polyester

and has a bound edge that has absolutely no give. That kind of strength is excellent for a

waist stay, but those edges can start to feel uncomfortable after many hours of

continuous wear depending on your tolerance of tight clothing.

Petersham ribbon is sometimes called “true grosgrain” and is

made of rayon and/or cotton. It is often

used in millinery applications and has a scalloped edge. In my experience, petersham makes for a much

more comfortable waist stay. (If you are

planning on laundering your garment, make sure to pre-shrink your petersham!)

I recommend using ribbon that is 1” or 1.5” wide. If a 2” wide ribbon is used at the waistline,

small darts may be used to shape the stay.

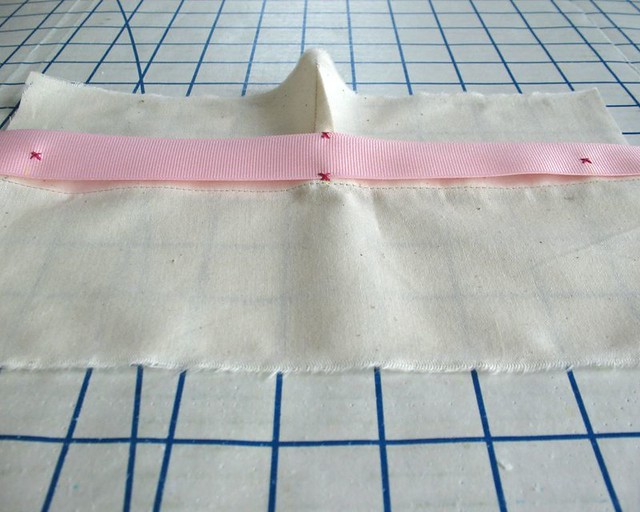

Starting at one opening edge, leave two or three inches of

grosgrain as a tail and pin in place.

Lay the grosgrain flat against the garment until you come to the first

stitching point. Pull the stay slightly

past that point so that the grosgrain is shorter in length than the garment

fabric and pin into place.

This will cause a bit of puckering when laid flat, but this

is what you want. Continue this process

until you reach the opposite opening edge, securing the ribbon with a pin at each seamline

and dart it crosses.

The stay should measure slightly smaller in circumference

than the waistline it stabilizes. Think

of two concentric circles – the inside circle circumference must be smaller

than the outer one in order to fit inside.

You may carefully measure your stay and divide up the ease between each attachment point (generally darts, tucks, or a seam allowance), but I usually just wing it.

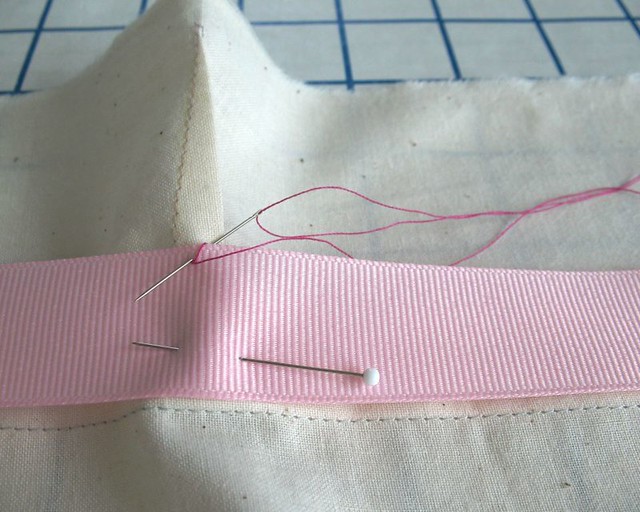

Using a reinforced cross-stitch, attach the stay to the

garment at each pin, making sure to only catch the seam allowance or dart so

that none of the stitches will show from the right side of the garment.

Cross-stitches may be stitched through the middle of the

stay, or at both edges. I often use a

combination of both options, depending on how my garment is constructed, how

many intersecting seamlines and darts/tucks are available to secure the ribbon,

and the width of the grosgrain ribbon.

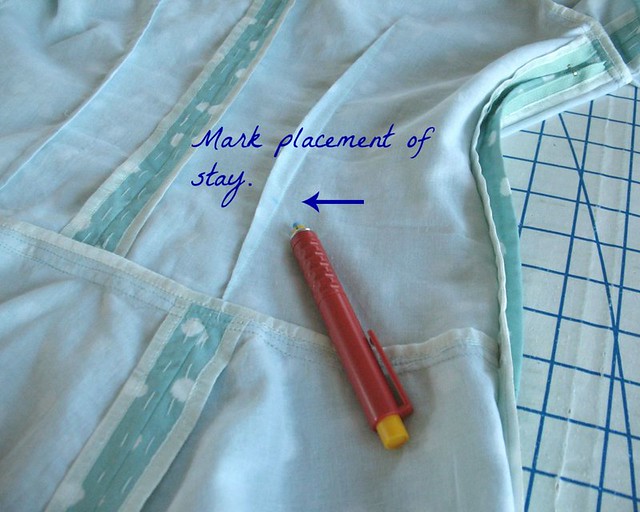

This particular dress has a dropped-waist, but the technique

is the same for a garment without an appropriately placed seamline such as a

princess seamed dress. For such a

garment, make sure to mark your waistline on the wrong side to ensure proper

placement.

A stay may also be inserted just under the bustline, as is the case with

this dress. The idea is that the stay is carrying some of

the weight of the garment so that it no longer hangs from the shoulders and/or upper edge and is

secured on the torso. This will also

help to keep the garment from rotating on the body during wear.

The easiest way to close the stay is with a hook & bar

closure. Make sure to stitch the hook so

it faces away from your body with the ribbon creating a barrier between your

skin and the metal.

Using smaller hook & eyes is a bit more time consuming,

but look so pretty!

The ends of the

ribbon may be used to cover most of the metal bits.

I like to off-set the opening of the waist stay slightly

from the zipper so the zipper teeth and metal hooks are not layered one on top

of the other.

Technically, a waist stay must be somewhat independent from

the garment and not stitched continuously to a seam allowance. However, every garment may not require a true

waist stay, and there are more basic options that will help to stabilize a horizontal

seamline.

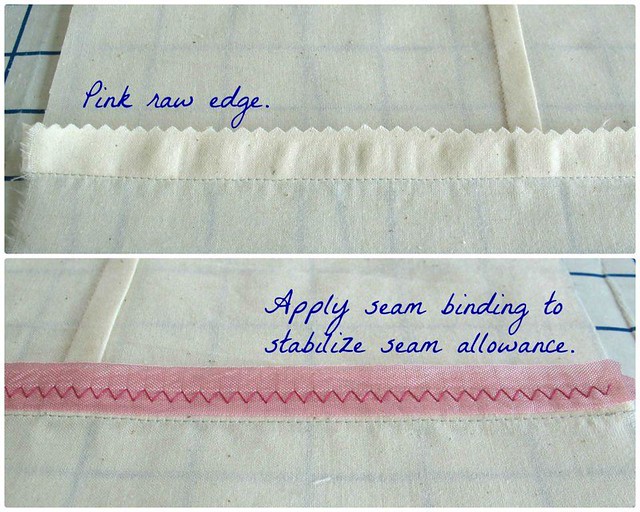

One such option is to use a length of seam binding or twill

tape. This is not as structured as a

true waist stay, but a quick pinking of the raw fabric edges and the addition

of the straight of grain binding keeps any cross seams from pulling apart, adds

stability, and helps to eliminate cross grain stretch at that seam.

A length of narrow grosgrain may also be used in this

manner. I would not, however, use this

technique with an invisible zipper because of the increased bulk the grosgrain adds

in the zipper seamline. You could,

however, terminate the stitching lines on the grosgrain an inch or so from the

opening and use a hook & eye closure as explained above.

Whichever method you choose, a waist stay is an excellent

addition to a garment that will help to increase the life span of your garments. I highly recommend adding this technique to your sewing arsenal!

[The fabric for this dress was received in exchange for my

contributions as a Britex

Guest Blogger.]