Today I have a tutorial to help you reinforce the curved

edge of a kimono sleeve. I have

mentioned this technique before, but thought it was deserving of a more in

depth tutorial.

I love a kimono sleeve. The design feature is classic, easy to wear, and very easy to construct. As a fan of vintage silhouettes, I have made quite a few dresses and blouses with this design feature over the years (the Anna Dress is a perfect example, as is this blouse, as well as my most recent project). But I have never liked the fact that it requires clipping into a seam that sees a lot of movement and potential wear.

There are, of course, different options for reinforcing a

non-gusseted version of a kimono sleeve. If your fabric is lightweight, a

French seam is an excellent choice. Because the seam allowance is trimmed

during French seam construction, the need to clip into the seam is eliminated. If, however, you find the perfect fabric for

your kimono sleeved pattern, but a French seam is going to be impossible with

your thick fabric, there is another way!

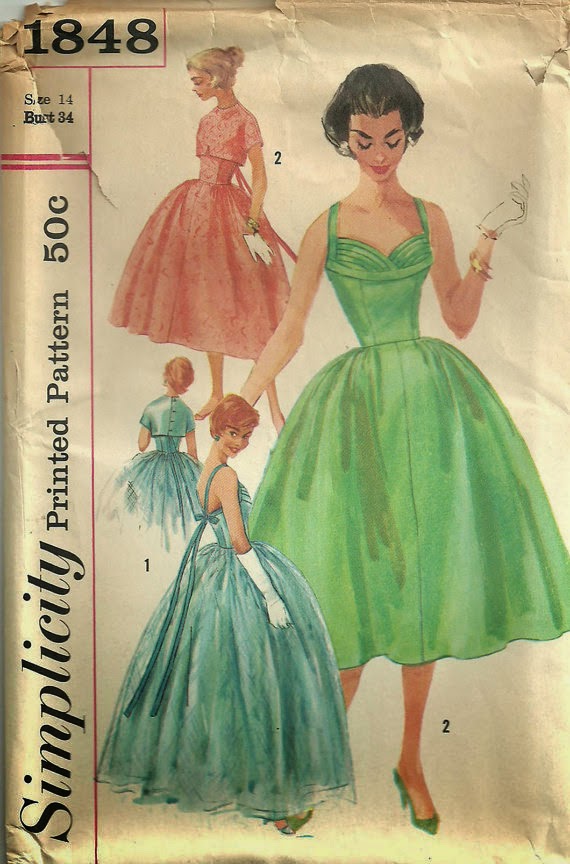

This reinforcement technique is often included on vintage pattern instructions; the first time I came across it was on the instructions for this dress. Over the years, I have used the process on many, many cut-in-one sleeved bodices, and along the way, I have figured out a few extra steps that makes the process easier, and (I think) even better!

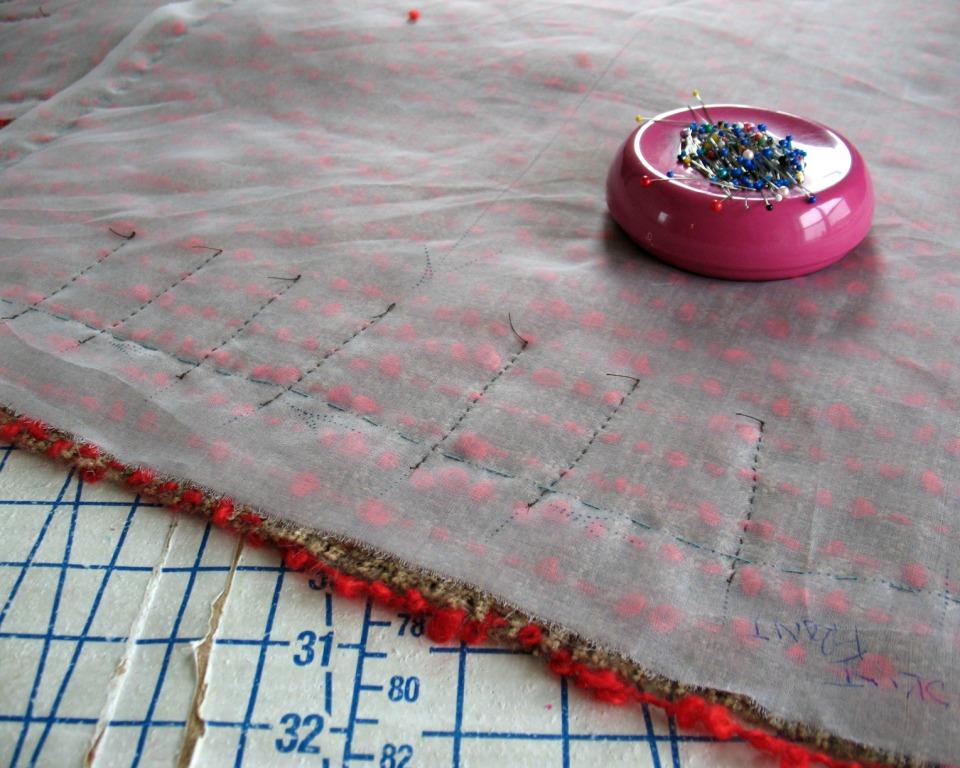

Before you start construction, stay-stitch each side seam on

the front and back bodice pieces (this step is not shown on the mini muslin mock up). Complete any construction necessary on the

bodice (darts, for instance) until it is time to close your side seams.

Stitch the side seam closed. For a side

seam zipper insertion, stitch the curved portion of the side seam from sleeve

opening to the top zipper opening.

At this point, pressing that seam open along the curve is

going to be next to impossible. And when

you turn the garment right side out, this is what you get.

The larger the seam allowance, the worse the pulling will be. It doesn’t look pretty, and it is certainly not

comfortable to wear.

In many situations, a second line of stitching just inside

the seam allowance is a great way to reinforce a seam. However, if you

need or want to press your seam allowance open (as in the case of a side seam)

this method will not work. Instead, stitch directly over your first line

of stitching using a small stitch length. It is not necessary to reinforce

the entire side seam, just the curved area that will be clipped.

Now it is time to clip into your seam allowance and release

the tension so the fabric lays flat.

Make sure not to clip past your stay-stitching! Some fabrics will

require cutting closer to the seamline than others. Wools, for instance,

tend to be quite malleable under the iron, while a tightly woven cotton may

require more cuts in order to lay flat.

Clipping into the curved seam is essential, but it weakens

the integrity of the fabric which can be especially problematic in an area that

sees quite a bit of movement. To

reinforce the clipped area, I like to top-stitch the curved section of the seam.

In many cases, the stitches will sink right into the fabric and are virtually

invisible, although they can end up being visible on certain fabrics.

However, most of the time this area will be covered by your arm, and without a

gusset, this type of sleeve has excess fabric to allow for movement that will

fold and create shadows, making that small bit of top-stitching disappear. Or, I suppose, you could even make the

top-stitching a design feature and continue it all the way down the seamline!

Press the side seam open – which should be easy to do once

those cuts are made! (A tailor's ham or sleeve board can be very helpful to press those curved seamlines.)

Now the side seam can lay flat along the curved underarm

area.

Pin the seam allowances in place from the right side of your

garment, making sure to catch all the bits of clipped fabric on the wrong side.

Top-stitch along the curved edge to reinforce the seamline.

If you are machine stitching, make sure to secure the thread

ends on the wrong side of the garment – you do not want that line of stitching

to come undone!

I like to add a second layer of protection which covers the

clipped edges (less direct friction on those raw edges will slow down the

fraying process). It also helps to reinforce the line of top-stitching,

especially on a loosely woven fabric. I often use a strip of rayon seam binding for this purpose. Twill tape would also work. For this

dress, I used a small scrap of silk organza that was handy. The added piece of fabric will also keep the seamline from pulling open.

Depending on the garment and/or my fabric choice, I will

hand stitch with a pick stitch or use the machine for this added line of stitching. Depending on the curve

of the pattern pieces, it can be much easier to manipulate the fabric by hand,

which also happens to make the stitching line less visible. Generally, my lining fabric gets a

machine application and my outer fabric gets hand stitched. But the choice is yours!

Because the fabric for this particular dress is very loosely woven and has

a tendency to fray, I treated the base of each clip with a spot of Fray

Check. I would not recommend doing this, however, if your garment does

not include a lining. The Fray Check can create a rough edge to the fabric

as it dries and would be rather uncomfortable on the underarm area without the

coverage of a lining material.

I like to repeat the top-stitching process on my lining as

well, eliminating the layer of added organza or seam binding from the equation. The lining is also an excellent chance to

practice the technique before working with your fashion fabric.

And that is one way to reinforce a kimono sleeve (or any clipped

seam that needs some extra security, for that matter)!

[The fabric for this dress was received in exchange for my

contributions as a Britex

Guest Blogger.]