Here are a few tips to help you tackle invisible zippers!

There seems to be an infinite variety of zippers out there –

the exposed zipper is getting a lot of attention these days on the fashion

front, but I generally prefer that the closure on a garment does not scream so

loud. An invisible zipper is an

inconspicuous option – it hides in the seam of the fabric so that all that

remains visible is the elegant pull tab.

If you need

to shorten your zipper, now is the time. [Something to keep in mind is that because

the invisible zipper turns inward, it is difficult to stitch in that fold the

closer you get to the zipping mechanism.

If I have an extra inch to work with and I am not fighting against the metal pull, I like to use it.]

To make it easier to access the zipper stitching line and keep the

folded invisible coils out of the way, you can iron the zipper open using a

low/synthetic setting on your iron with no steam. I usually take a quick pass at my invisible

zippers with an iron, but do not attempt to flatten them since it can affect

the integrity of the zipper. Also, too

much heat can melt the teeth together, ruining the zipper (please don't ask me how I know that!).

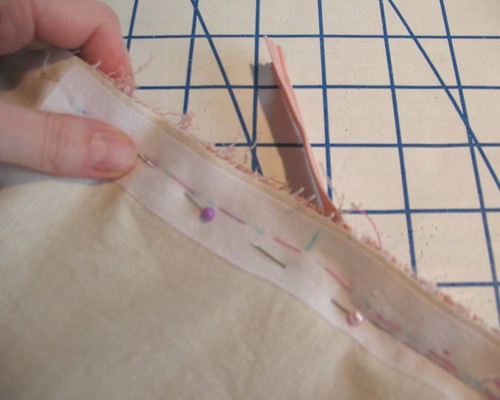

The trick I find most helpful for installing (any) zipper is

to reinforce the opening edges of the garment. Invisible zippers, especially, have a tendency to pooch out at odd angles in lighter weight fabrics that have not been stabilized.

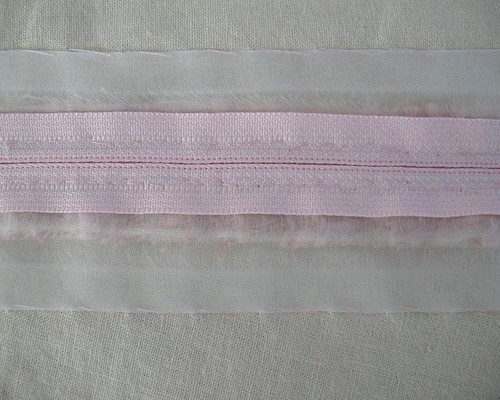

A strip of silk organza is an excellent option, as is a strip of fusible

interfacing (make sure to choose an appropriate weight for your garment

fabric). The strip needs to be wide

enough to extend beyond either side of the seam fold so that the stitching line

will catch your chosen stabilizer. For

an invisible zipper, one inch is plenty.

Also make sure that the interfacing is longer than the zipper

opening. The point where the fabric seam

meets the zipper opening is likely to get a lot of stress and the interfacing

will help to reinforce that spot.

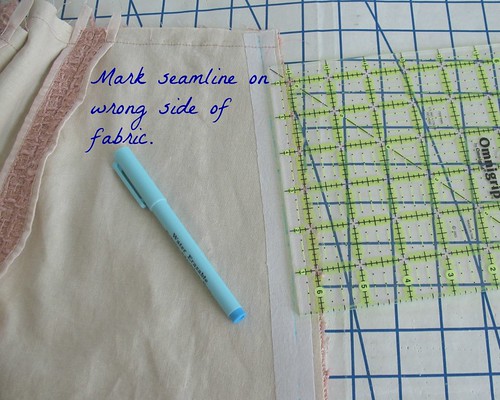

Mark just inside the seamline (depending on your fabric, a

fabric pen, chalk, or even a pencil will do the trick). For an invisible zipper, this line will need

to be visible on the right side of the fabric.

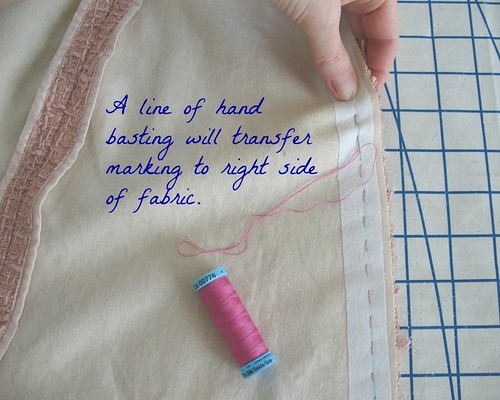

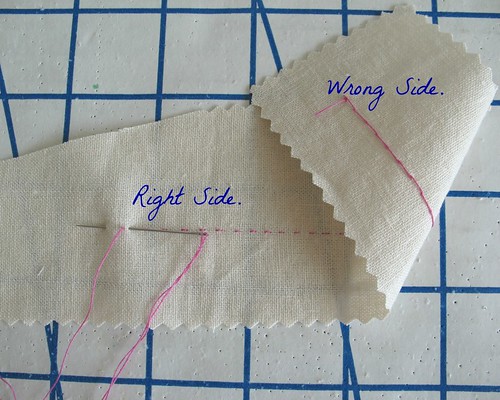

This particular fabric is not easily marked, so I drew my mark on the wrong side and basted that line with thread. This makes the line visible on the right side of a highly textured fabric.

If there are horizontal seams that cross your zipper opening, trim your fabric layers, and baste those horizontal seams in place.

I find the easiest way to figure out which way to insert the

zipper itself is, with the right side facing and the zipper next to the opening

seam, right side up. When I begin to fold

the seam allowance away from me (to the wrong side where it belongs) the zipper

should disappear, leaving the pull tab visible.

In other words, the tape edge should be close to the raw edge of the

fabric, and the zipper coil should be just hanging over the marked seamline.

The second most important part of zipper installation is

basting, which saves a massive amount of time in the long run – so don’t skip

this step! I like to use a contrasting

silk thread so it is easy to remove later on.

Once one side of the zipper is basted in place, it is time

to stitch it down. Many machines come

with an invisible zipper foot. If you do

not have one, a regular zipper foot can do the trick, depending on how mobile

your needle is. The stitching line needs

to get as close as possible to the plastic teeth without grabbing them. I do not recommend the plastic invisible

zipper kits that only cost a few dollars – the plastic slide can move around

while you sew which is extremely frustrating.

Another option is hand stitching. I know the first time I heard of someone hand

stitching a zipper I thought they were crazy.

But a tiny backstitch/pick-stitch/prick-stitch is incredible sturdy and

works beautifully. It also gives you the

most control.

One thing that will help to ensure a beautiful application

is to stitch both sides of the zipper in the same direction. If you start from the top and work your way

down on the right hand side, work from the top down on the left side as well. This will help to keep your fabric from

shifting in opposite directions. If you

have trouble matching seamlines, this may solve your problem!

Speaking of seamlines . . . if you have any horizontal

seamlines to match, you will want to mark those after one side of the zipper is

stitched into place. Close the zipper,

and mark the seamline point on the zipper tape with a fabric pen or chalk (I

prefer a fine point pen – the thinner the mark, the more accurate the placement).

Matching any seamlines necessary, baste the second tape into

place.

Now make sure to zip everything

closed to check that those seamlines are matching up! If not, remove the basting and try again.

Once you are happy with the zipper placement,

stitch it into place, remembering to stitch this seam in the same direction as

the last.

Next you will need a standard zipper foot to close up the

seam below/above the zipper. Remove the

basting stitches, and push the end of the zipper out of the way.

Pin the seam closed below your newly installed

invisible zipper. The end of this seam

should overlap the zipper stitching slightly.

As a final note, I will say that I prefer to install

invisible zippers in an open seam. I

find it much easier than fighting with the twisting coil against a closed

seam. If possible, I will insert a

zipper before adding other pattern pieces to the mix. This is not always possible, but the less

fabric you have to flip around, the easier it will be!

Things do not always go according to plan, as evidenced by

this project. As much as I love the look

of an invisible zipper, they are far from sturdy. I had a feeling that this fabric was too

bulky for an invisible zipper, but my stubborn streak thought I could make it

work – the dress had different ideas.

Instead of fighting to get it open and closed every time I wear the

dress, I decided a lapped zipper would be a much safer bet.

The problem was that the loose weave of the fabric was

coming apart and a lapped zipper needs plenty of seam allowance to work

properly. So out came the silk

organza. I ripped a two inch strip and

applied it to the raw edges. When turn

under, it covered the raw edges

Crisis averted!

Invisible zippers are brilliant tools, when used with a

suitable project; when installed properly,

they are virtually undetectable. But they

are best used with light to mid weight fabrics.

Close fitting garments may require an extra pair of hands to zip them up

or the help of a hooked waist-stay. I

have a number of vintage invisible zippers with metal teeth which are a bit

stronger, but they still have to twist inward in order to close which is not

nearly as stable as a standard zipper.

And should your invisible zipper application go completely

awry, step away from the project for a chunk of time and then have at it with a

seam ripper. The invisible zipper is a

fickle mistress – worth the effort in certain circumstances, but she definitely

has a mind of her own!

Do you have any invisible zipper stories of your own?

[The fabric for this project was received in exchange for my

contributions as a Britex Guest Blogger.]